Save Costs with a Customized Warehouse Inventory Management System

Avoid unnecessary stock, rush shipments, and equipment downtime with customized warehouse inventory management. Fill orders fast with real-time inventory tracking.

Behind labor, inventory is the second most significant cost for a business. You can pay a worker 1/12 of his annual salary month by month as your sales come in. You pay for inventory upfront and only see the cash come back once it’s sold.

Managing inventory is vital to your business, especially when defending your margins becomes the difference between cash flow and cash burn.

Simple Inventory Management by Customizing Your Real-Time Inventory Tracking:

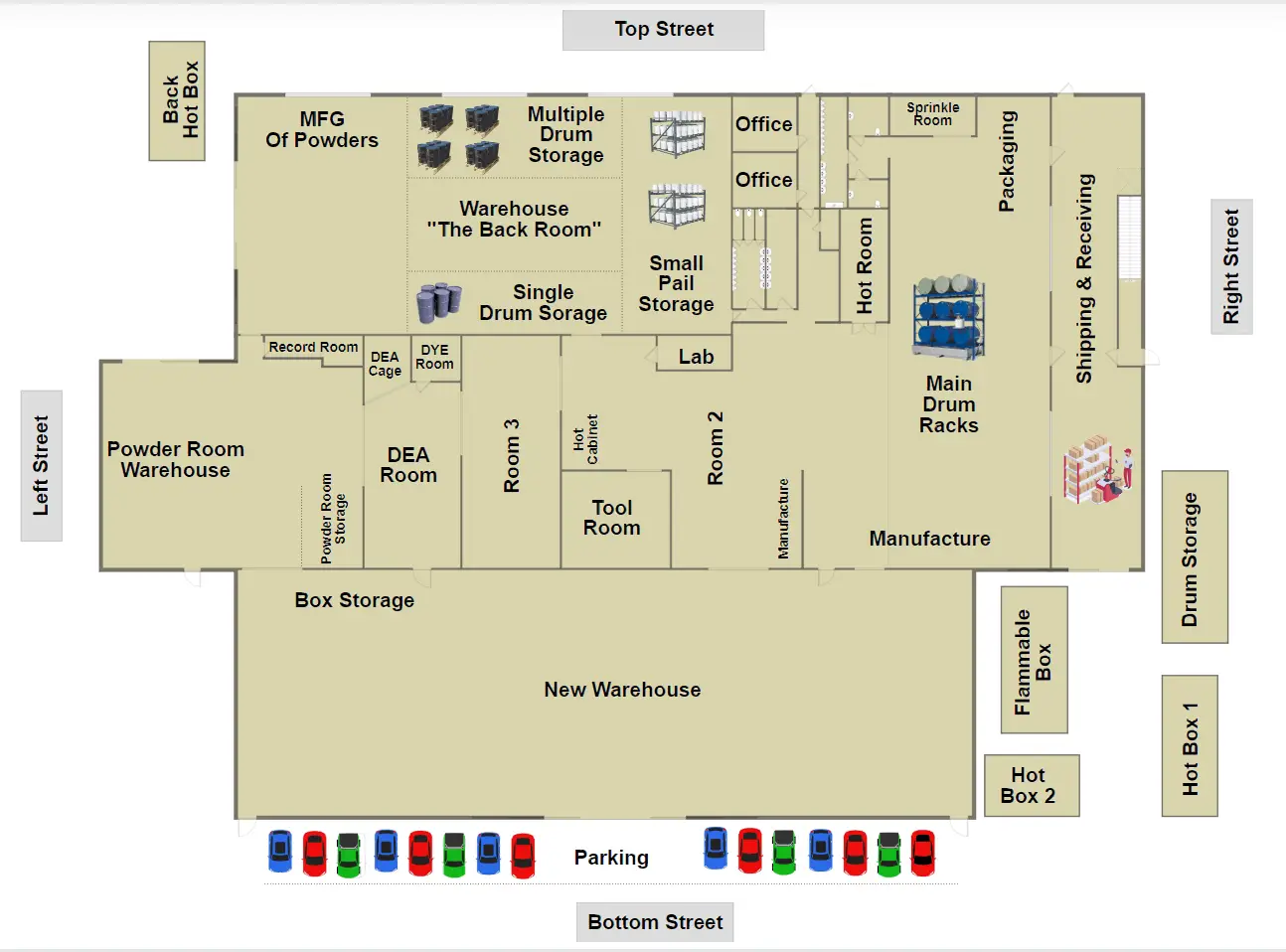

The best way to track what you have at any given time is to put the floor plan of your specific storage area on a computer screen. Click on any room to see what is inside that room at any moment. Search for an item, and the spaces it’s located in will light up.

To prevent shortages, if you are running low on something, the system will alert you, purchasing, or your supplier directly.

Once you know where everything is at all times and how much you have of it at any moment, warehouse inventory management becomes a cinch.

We developed our ERP Net Warehouse Inventory Management system for this purpose. One of our client's biggest challenges is losing track of a single item, and production has to be frozen until it is found.

ERP Net was also designed with customization in mind. Any one size fits all standard software solution cannot consider that each business has its storage facility and stores its items differently.

Why should you have to fit your inventory management around the software? Isn’t that exactly how items get lost?

What Customization Can Do for Your Warehouse Inventory Management:

Take a look at the floor plan of the warehouse of a manufacturing company:

The top-level feature is that you can click on any room, and a table will appear that tells you what’s in that room and how much of it you have. You can also click on a search bar to enter an item; the system will tell you where it is.

Now, let’s get down to customization.

What if your floor plan isn’t the same as this one?

What if you store 30% of your inventory in 70% of your storage and 70% of your supply, which can consist of thousands of parts – some of them in the form of 3mm screws the length of your fingernail, in a relatively smaller area?

You need a more thorough floor plan.

Designate closets inside rooms and see what inventory is stored in the left closet of the back room or the middle closet of the tool room. You may want to classify according to shelves inside closets.

Customization is the key to effective warehouse inventory management.

ERP Net lets you add as many storage areas as you like. When looking for a 6mm screw, it can tell you according to the drawer it is in.

This saves you time, manpower, and headaches.

When Nothing Stays in One Place:

Inventory is always moving.

Your inventory management system must keep up. ERP Net lets you move something from one place to another with ease. It also enables you to move some of an item to another place.

When you search for an item, you want to see multiple rooms or areas light up if it is in several places at once.

Customization becomes critical because different businesses have different regulations to follow. Some items cannot be stocked in certain places or next to certain materials.

A custom Warehouse Inventory Management system lets your storage facility talk to your suppliers, accounting team, billing department, and manufacturing process. ERP Net can alert billing to send the invoice when finished products leave the warehouse.

By tailoring your software to fit how you manage inventory, you can keep your inventory levels lean and your cash levels flush.

Saving your business time and money constantly with a Warehouse Inventory Management System customized to your business is what we specialize in. I am happy to talk with you about it at your convenience so please feel free to contact us.

Comments